Flex Circuit Boards Different From Rigid Boards

A flex circuit board allows for the flexibility of connecting components in multiple axes. This can greatly reduce the stress on the board, eliminating issues like solder joint failure. They are also lighter and thinner than rigid PCBs and can fit into unique or space-constrained form factors. In addition, they can help to absorb and lessen the impact of vibrations on the circuit, making them suitable for use in harsh operating environments.

The basic materials in a flex circuit board consist of the core, insulators and conductors. The core is made from a flexible polymer such as polyimide, polyester or polyethylene naphthalene. It provides the structural base of the flex circuit and is typically laminated with an adhesive. Insulators separate electrical conductors without conducting current themselves and are used to protect the underlying layers from damage and corrosion during the fabrication process.

Conductors are the metal layers that transmit electricity. Most are copper but a variety of other metals can be used. The conductors are etched onto the insulator layers in a pattern specified by the design. A layer of coverlay then insulates the conductors and protects them from contamination. This may be a conductive epoxy, a silk screen or another material.

How Are Flex Circuit Boards Different From Rigid Boards?

Some flex circuits have a single-sided configuration with only one side of copper. This is the most common type of flex circuit and is suitable for many different applications. These circuits are typically laminated with an adhesive-based polyimide coverlay.

More complex flex circuits can have double-sided copper or multilayer constructions. They can include openings called blind or buried vias to connect the inner layers to each other without passing through the outer layer. Blind and buried vias are useful in reducing the aspect ratio of complex through-hole patterns, which can be a significant cost-driver for certain designs.

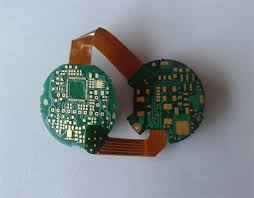

Rigid-flex circuits can be constructed from a mix of both flexible and rigid materials. They combine the benefits of both and are able to fold in on themselves, allowing them to fit into a smaller form factor or to accommodate tight connections. Rigid-flex circuits can be useful in a wide variety of electronic products, including smartphones and IoT wearables.

It is important to consider the capabilities of a flex circuit board and how it will be used in your project before deciding whether or not this is the best option for your product. If you do not require bending or folding capability or high-density component mounting, alternative options such as a traditional rigid PCB or a fully flexible circuit may be more suitable.

A flex circuit is more expensive to manufacture than a rigid board, so you will want to make sure that it meets your product requirements before committing to this construction method. The manufacturer you choose should offer detailed calculators to help you understand how much a flex circuit will cost before the manufacturing process begins. For example, PCBway offers a tool to estimate the total cost of your design based on the layers required and the thickness of the conductors.